Everything You Need to Know About Loose Wheel Nut Indicators

Why Were Wheel Nut Indicators Invented?

The first loose wheel nut indicator was invented in the 1990's in the United Kingdom by Mike Marczynski, a fleet manager of small commercial vehicles, who after a near miss with a wheel detachment on one of his vehicles, identified the need for a device that would help prevent wheel loss. Further development introduced the specific melting point of the plastic of the device to indicate overheating problems caused by issues with wheel bearings or brakes. Over time developments of the wheel nut retainer and the wheel nut locker have added to the range of products available to fleet managers and drivers today. This simple device provides a solution for today’s vehicle safety procedures for commercial and recreational vehicles in the transport, construction, mining and agricultural industries.

What Are Loose Wheel Nut Indicators, Retainers and Lockers?

Trusted Safety and Reliability

Explore our full range of Wheel Nut Indicators – all sizes available.

Shop Now

A Dust Cap Long Reach Loose Wheel Nut Indicator - indicates and protects

A standard indicator with a long reach barrel and a protective cap. This device indicates a nut is loosening or overheating and protects the nut and stud from corrosion and general road damage.

Dust Cap Wheel Nut Indicators

Protect against dirt and moisture while maintaining reliability – multiple sizes available.

Shop Dust Cap Indicators

How Are Wheel Nut Indicators Beneficial to You

After wheel nuts have been torqued to the recommended manufacturer specifications, fitting loose wheel nut indicators, retainers or lockers over each nut on every wheel of your vehicle will provide a quick and reliable method of checking that all nuts are secure during an inspection. The primary benefit of wheel nut indicators is enhancing safety. Loose wheel nuts can lead to wheel detachment so installing wheel nut indicators will serve as an early warning system helping to prevent potential wheel loss. These fluorescent yellow plastic rings are affordable and will help save time and effort in checking all individual nuts and reduce costs on repairs, replacements, and potential legal liabilities that might arise from accidents. For businesses with a fleet of vehicles, wheel nut indicators can improve the overall efficiency of the fleet management process. They are helping to implement a proactive maintenance approach and help businesses comply with specific regulations or industry standards in vehicle safety.

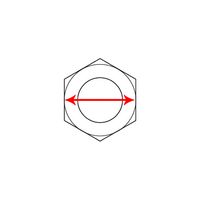

Measuring Wheel Nuts

Installing Wheel Nut Indicators

Install Indicators in a Uniform Pattern

Inspecting Wheel Nut Indicators

Inspect each wheel regularly for any change in your chosen pattern and look for:

- misalignment will indicate a loose wheel nut, - damaged, warped or melted may indicate overheating, - missing indicators may mean lost, broken or stripped studs or nuts. Please Note: Wheel nut indicators only assist routine safety inspections and DO NOT replace proper maintenance. It is important to remove all indicators before performing torque checks.

Summary

Overall, wheel nut indicators are crucial in maintaining vehicle safety, preventing accidents, reducing maintenance costs, and reassuring drivers and fleet managers. It is essential to regularly inspect and replace these indicators as needed to ensure their effectiveness.